Description

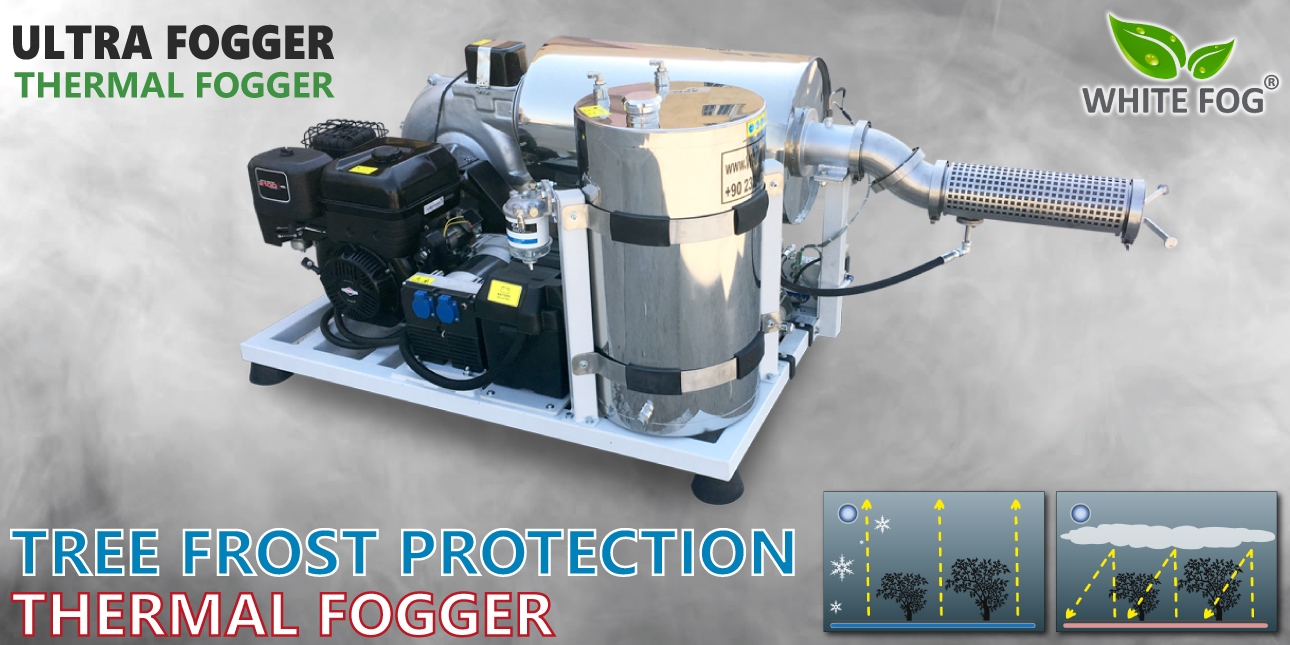

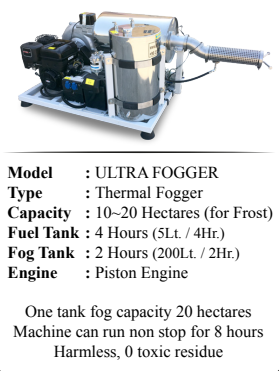

ULTRA FOGGER thermal fogging machine is designed for large-scale agricultural areas. Mounted on a vehicle or tractor, it effectively protects crops and agricultural land over an area of 10 to 20 hectares.

It provides full protection against frost down to –7°C, and partial protection in even colder conditions.

ULTRA FOGGER is currently the highest-capacity thermal fogging machine exists in the world, equipped with a 10 HP Briggs & Stratton Vanguard engine, of which White Fog is the sole manufacturer. 1 tank fill can protect to 20 hectares, generating a dense, highly protective artificial cloud. This technology creates a controlled microclimate above the crops, providing effective protection against frost conditions.

It surrounds trees, flowers, and buds with a three-dimensional thermal cloud, forming a cold-resistant protective layer. The machine generates a curtain of artificial clouds above the plot, reflecting thermal radiation (electromagnetic radiation) back toward the soil and preventing heat loss from the ground.

The artifical cloud stays suspended in the air for 3 hours, providing full protection down to –7°C. Below –7°C, it offers partial protection.

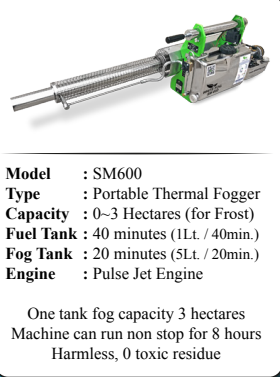

- The SM600 is suitable for frost protection of small agricultural areas.

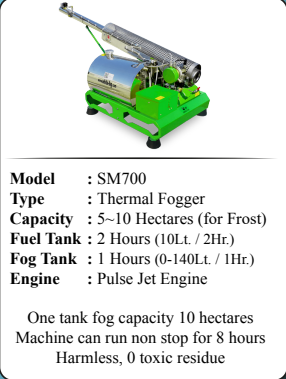

1 SM600 unit covers up to 0–30 decares (0–3 ha). - The SM700 is suitable for medium-sized areas.

1 SM700 unit covers up to 50–100 decares (5–10 ha). - The ULTRA FOGGER is suitable for very large areas.

1 ULTRA FOGGER unit covers up to 100–200 decares (10–20 ha).

For further technical details, expert information, and videos please visit our main English website www.whitefog.com

What is agricultural frost and why does it occur?

Agricultural frost occurs when the temperature drops below the freezing point in agricultural areas, causing the water contained in plant cells to freeze. Water freezes at 0°C, and below this temperature, water molecules solidify. This freezing causes plant cells to expand, which can tear cell walls and damage flowers and buds. Even when flowers or buds do not die immediately, frost can alter the cellular structure, making the plant more vulnerable to diseases and pests.

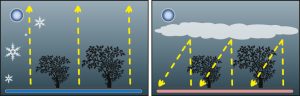

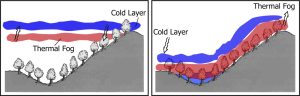

In the vast majority of cases, frost observed in agriculture is radiation frost. It occurs during calm, windless, and cloudless nights. Under these conditions, the heat accumulated in the soil escapes by radiation into the atmosphere, while cold air, which is denser and heavier, accumulates and stagnates at crop level. In the presence of clouds, this phenomenon is eliminated, because clouds prevents the cold air mass from settling on plants and limits heat loss from the soil to the atmosphere. 90% of agricultural frost episodes are related to radiation frost.

How does ULTRA FOGGER thermal fogger machine protect against agricultural frost?

As mentioned above, thermal fogging machines spray an antifreeze oil liquid in the form of an artificial cloud. The antifreeze oil vapor turns into very fine particles, creating an invisible protective layer around trees and flowers. This layer prevents water molecules from condensing and freezing on flowers and seeds.

This method does not change the other properties of water. The antifreeze vapor is not toxic, does not damage cells, and leaves no harmful residue. This type of solution, for example based on vegetable glycerin, is also used in the cosmetic and food industries.

In addition, in clear and windless weather, heavier cold air masses tend to descend onto crops. Warm air near the soil, being lighter, rises, while colder, denser air descends. The mist generated by the machine acts as an artificial cloud curtain, positioning itself between these two air masses and remaining stable above the plants. This cloud curtain covers crops like a thermal blanket and:

- Pushes back cold air and prevents it from collapsing onto plants,

- Reflects plant heat back toward the ground, preventing heat loss,

- Uses the antifreeze effect of the mist to delay and prevent the freezing of water molecules inside plants.

What are the advantages compared to frost fans, irrigation systems, straw and tire burning, and other thermal fogging machines?

Frost fans:

Frost fans can provide protection in moderate frost conditions, up to –4°C. However, when temperatures drop below this level, frost fans lose their effectiveness. They work by mixing warm and cold air, creating molecular movement and air circulation in the air mass. This produces a limited heat transfer aimed at reducing frost damage.

When temperatures fall below –4°C, there is no longer enough warm air available to mix, making it impossible to protect flowers and fruit tissues. In such conditions, operating the fans can actually convert radiation frost (calm air frost) into advection frost (windy frost), which may cause more burning and tissue damage to crops.

Frost fans are also very expensive. Unit prices start at around €30,000, and a single fan can protect a maximum of 5 hectares (50 ares). To protect a 20-hectare area, four fans are required, bringing total equipment costs to about €150,000, excluding site preparation.

In addition, for safety reasons, frost fans automatically shut down even in light wind conditions to protect themselves. Installation is another major disadvantage: the system requires a strong electrical infrastructure or a powerful generator, resulting in extra costs and time for site works, cabling, and infrastructure. On rented land, such investments are often non-recoverable, creating a serious economic and operational disadvantage.

Irrigation method (sprinklers):

The irrigation method can provide some protection in moderate frost, down to –4°C. However, in severe frost below this range, its effectiveness drops sharply.

At –6°C and lower, instead of protecting flowers and fruit, irrigation can increase frost damage, causing burning and death on branches and tree surfaces.

One of the most critical weaknesses of this method is the risk of power cuts, water interruptions, or pump failures. If irrigation stops suddenly, wet surfaces freeze much faster and more deeply, which can result in the complete loss of branches and young trees. For this reason, irrigation is considered a high-risk frost-protection method.

Burning straw or tires:

Using straw or tire burning to fight agricultural frost is labor-intensive and logistically difficult. It requires serious preparation in advance and often leads to delayed response.

This method produces smoke by direct combustion. Fire does not warm crops in a controlled way to create beneficial evaporation; instead, it breaks down the material at a molecular level and produces dry, fine-particle smoke. Straw and tire smoke consist of micronized particles about 1 μm in size, similar to cigarette smoke.

Because of this small particle size, the smoke drifts away quickly and does not stay suspended over the field. Since it is dry, it has no anti-freeze effect and cannot form a thick insulating layer capable of retaining heat.

By contrast, our thermal fogging machines do not burn the liquid. They heat oil-based fluid in a controlled way, producing a moist, dew-like vapor with a strong anti-freeze effect. The fog particles range from 1 to 100 μm, allowing the fog to stay suspended at different heights and form a dense, three-dimensional artificial cloud layer.

Because of the larger particle size, this artificial cloud forms a much thicker and more effective barrier than straw or tire smoke, trapping radiation (heat) far more efficiently. While straw or tire smoke acts like a thin sheet, the fog produced by our machines works like a thick blanket, providing far superior frost protection. The denser, thicker, and more multi-sized the artificial cloud layer is, the higher the success rate against agricultural frost.

Other smoke machines or homemade systems:

Some farmers attempt to produce smoke by dripping diesel fuel into a tractor exhaust. This method is technically incorrect and highly risky. Fuel or oil in the exhaust causes carbon buildup and lubrication failure in pistons, rings, and cylinder walls, leading to rapid engine wear. In practice, tractors using this method often become unusable within two years.

The oil flow that can be fed into the exhaust is technically limited to about 20 liters per hour, which is far too low to create a smoke density and particle concentration sufficient to form an effective frost-protection layer.

Furthermore, exhaust heat does not vaporize the oil under proper conditions, so the resulting smoke is dry, not moist. Dry smoke has no anti-freeze effect and provides no real protection.

LPG-powered or low-quality thermal foggers:

These technics also fail to produce effective smoke. LPG systems cannot operate in low temperatures because LPG tends to freeze around –1°C, making frost protection impossible. Low-quality thermal fogging machines only produce visible smoke, but not a functional artificial cloud layer. Fog density alone does not equal frost protection. Dry, burnt, homogenous, overly fine particles offer no defense against radiation frost. White Fog machines are professional frost-protection systems, unlike conventional thermal foggers that simply produce smoke without these qualities.

Requirements for effective frost protection:

For effective agricultural frost protection, the following are essential:

- Vaporizing fog oil at the correct temperature range without burning it

- Spraying the vapor in a moist state, without overheating

- Producing particles of the proper micron size

- Creating a dense and thick artificial cloud layer

The higher the oil vaporization capacity (flow rate) of a thermal fogging machine, the greater the protection it provides.

Our thermal fogging machines provide three layers of protection: reflector effect, anti-freeze effect, and inversion effect.

White Fog machines fully protect crops down to –7°C in calm conditions and provide partial protection even at –10°C. By increasing the number of machines, reducing plot size, and using suitable fog oils, the success rate can be increased even further.

Advantages of White Fog thermal fogging

- Ensures full protection down to –7°C and partial protection at even lower temperatures

- Creation of a dense, uniform white cloud over 3 ha (SM600) up to 20 ha (ULTRA FOGGER)

- Effective within 30 minutes: rapid cloud formation to protect crops before frost occurs

- Plant-safe antifreeze: no toxicity, no residue, no damage to flowers or buds

- Mobile and practical: hand-carried, shoulder-carried, tractor-mounted, easy to install on different plots

- Reliable: service life ≥ 15 years, spare parts and service available locally

For further technical details, expert information, and videos please visit our main English website www.whitefog.com

Tree Frost Protection Fruit Protecting Freeze Boiler Fans

Frost Protection Thermal Fogger Generator Device Machine

Reviews

There are no reviews yet.